The FFS rigid films market is segmented into North America, Latin America, Europe, Asia Pacific, and MEA. North America leads due to food industry demand, while Asia Pacific sees growth from China and India. Europe grows sluggishly; MEA and LATAM show steady growth.

NEWARK, DE / ACCESSWIRE / January 8, 2025 / The global FFS rigid films market is poised for substantial growth, with its market size estimated at USD 26.3 billion by 2025, reaching an impressive USD 38.4 billion by 2035, according to the latest industry projections. Sales are expected to increase at a steady CAGR of 4.3% during the forecast period from 2025 to 2035. In 2024, the market generated a total revenue of USD 25.2 billion.

A long range of packaging applications with FFS rigid films have become easy and less complex. As packaging becomes another way of advertising and a good packaging solution can help product gain more traction, FFS rigid films are used in packing pharmaceutical goods and food items along with some hardware equipment.

Made from materials such as PE, PET, and CPP, FFS rigid films act as barriers to moisture or any other fluid. The higher adoption of FFS rigid films is attributed to their thick ad durable nature, which can carry heavy materials without any leakage. Companies now produce semi-rigid and rigid laminate films that are flexible and can be used in medical and pharmaceutical products.

These films are puncture resistant and enhance their barrier properties and processabilities. Providing convenient handling and durable product protection and storage helps the industry experiment and enhance their product's performance, fueling the demand for FFS rigid films. These rigid films come in different variants, such as transparent, printed, or coloured.

Efficiency and Sustainability

The vendor brands now focus on creating budget-friendly packaging solutions along with taking care of the ecosystem. Higher compliance policies have led manufacturers to adopt eco-friendly materials. This also includes the adoption of a sustainable process unit that has lower emission levels along with sustainable packaging.

Higher Puncture Resistance

Due to the thick layer of PE, PET, and CPP material, the chance of leakage becomes minimum. Companies produce extra thick layers to make it look stabilized and attractive while also guarding the product from any moisture, air, and object. This thrives in sales of FFS rigid films in new regions. The thick layer doesn't puncture around pricky objects, making it suitable for lamination or packaging solutions for pharmaceuticals goods and samples.

Lower Package Weight & Density

The reduced density has led to the lower weight of the packaging solutions, involving the large range of gauges that holds the packaging together. This makes the rigid films hold very good processability on form-fill-seal machines (FFS) - excellent deformation properties. The good cutting properties have also made this sort of packaging mainstream, fueling the demand for FFS rigid films.

FFS Rigid Films Market Overview

The high barrier packaging industry is rising throughout the globe owing to growing demand for packed foods. FFS rigid films ensure that the product is safe from external and internal effects which increase degradation. FFS rigid films avoid the infusion of gases including oxygen and water vapor.

FFS rigid film is used for high barrier flexible packaging because of its excellent protection and freshness maintaining ability for long-term of the product, organoleptic, and outstanding gas barrier property.

The reflexive property of these FFS rigid films and their ability to the preservation of products for a longer period make them a preferable choice in the food industry. FFS rigid films are perfect solution for efficient, functional and attractive packaging based on low costs and inventive approaches.

During the packaging of food different gasses such as O2, CO2 andN2 are used alongside the pack to extend the shelf-life and appearance of the product.

FFS rigid films used for packaging the meat and meat products, poultry, seafood, dairy products, and fruits and vegetables, where the chance of degradation in the quality of food is too much more. For providing the better protection of food FFS rigid films gain the popularity in the market and its market expected to grow during the forecast period.

Explore In-Depth Analysis - Click Here to Access the Report!

https://www.futuremarketinsights.com/reports/ffs-rigid-films-market

Understanding The FFS Rigid Films Market

The term "FFS Rigid Films Market" refers to the market for Form-Fill-Seal (FFS) rigid films, which are used in the packaging industry. FFS technology is a process in which a film is formed into a package, filled with a product, and then sealed, all in a continuous operation. Rigid films in this context are typically used for packaging products that require a sturdy and protective outer layer, such as food, pharmaceuticals, or consumer goods.

These films are usually made of materials such as polyethylene (PE), polypropylene (PP), or other durable plastics. The FFS rigid films market encompasses the demand, supply, and growth trends of these films, focusing on industries where the use of rigid packaging solutions is essential for product safety, freshness, or shelf appeal. The market is influenced by trends in food packaging, e-commerce packaging, and sustainability initiatives in packaging materials.

"The FFS Rigid Films Market is experiencing significant growth, driven by increasing demand for efficient packaging solutions. With its versatility and sustainability, FFS rigid films are becoming the go-to choice for industries looking to enhance product protection and shelf appeal." Says a Lead Consultant Ismail Sutaria in Packaging at Future Market Insights (FMI).

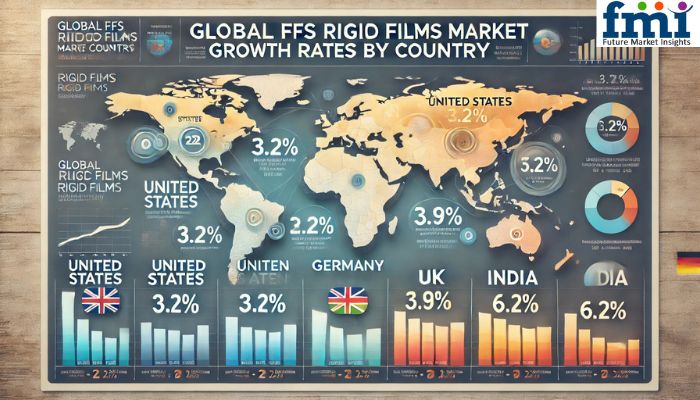

Market Value of FFS Rigid Films by Country

Countries |

Value CAGR (2025 to 2035) |

USA |

3.20% |

Germany |

2.20% |

China |

5.40% |

UK |

3.90% |

Spain |

3.10% |

India |

6.20% |

Canada |

4.50% |

Key Takeaways From the FFS Rigid Films Industry Report

The FFS rigid films market grew at a CAGR of 3.1% from 2020 to 2024, reaching USD 25.2 billion in 2024 from USD 22.2 billion in 2020.

China is projected to lead East Asia in FFS rigid films market growth, with a CAGR of 5.4% by 2035.

The UK retail industry presents significant growth potential, with a forecasted CAGR of 3.9% during the evaluation period.

Polypropylene (PP) is expected to dominate the market, holding a 35.7% share during the forecast period.

FFS rigid films with thicknesses between 50 to 150 microns are estimated to account for 44.7% of the market share in the assessment period.

Lightweight Creates a Buzz for the Sales of FFS Rigid Films

Manufacturers are growing the food industry by providing premium quality FFS rigid films as per their requirements in recent years. The FFS rigid films are high-barrier food packaging developed by key manufacturers all around the globe during the forecast period.

Several top manufacturers in food companies are developing the FFS rigid films to save food products from external and internal effects. Their flexible packaging and long-term freshness of food drive the demand by several end-users such as hotels, restaurants, and others.

In recent years, the essential key players have been making these rigid films by avoiding infusion gases, including water vapor and oxygen. It seems the best choice for restaurants and hotels to provide outlet services to their customers with an excellent solution.

Moreover, the food industry has been making preferable choices in adopting FFS rigid films in recent years. Key players are developing innovative FFS rigid films with a reflexive property that can preserve the food for a longer time with attractive packaging.

However, the manufacturers will likely provide lightweight, low-cost, efficient, and functional rigid films that have driven end-users demand in recent years. FFS rigid films can increase the shelf-life of the products by using different gases while packaging foods such as CO2 & O2.

Furthermore, the food manufacturers are developing these rigid films for veg and non-veg food items such as meat, poultry, seafood, vegetables, fruits, and others. Without changing the taste and quality of food, these rigid films are a key solution that provides better packaging by manufacturers.

Nowadays, the FFS rigid films are popularly growing the market share in recent years by consumers as they fulfill their requirements with premium quality. In addition, the manufacturers of FFS rigid films are likely to increase their production all around the globe by observing their customer's needs during the forecast period.

These manufacturers are focusing on the end-use industries and making several experiences to try and innovate different types of rigid films that satisfy their customers during the forecast period.

Exploring the Prominent Factors Boosting the FFS Rigid Films Market

Rising Demand for Convenient Packaging Solutions: Consumers increasingly prefer ready-to-use, single-serve, and easy-to-open packaging, driving the adoption of FFS rigid films in various industries, particularly food, pharmaceuticals, and personal care.

Growth of the Packaged Food Industry: The expanding global packaged food industry, driven by urbanization and changing lifestyles, is fueling the need for durable, cost-effective, and efficient packaging solutions like FFS rigid films.

Technological Advancements in FFS Machinery: Improvements in FFS machinery, such as high-speed production and better sealing capabilities, are enhancing the efficiency and quality of packaging, boosting the demand for compatible rigid films.

Increased Focus on Product Shelf Life and Protection: FFS rigid films provide excellent barrier properties against moisture, oxygen, and contaminants, which help in extending the shelf life of perishable products and maintaining product integrity.

Sustainability Trends in Packaging: The development of recyclable and eco-friendly FFS rigid films is aligning with growing consumer and regulatory demand for sustainable packaging, further driving market growth.

Competitive Landscape

Key companies in the FFS rigid films sector are creating and launching new goods to the market. They are combining with various organizations and expanding their geographical reach. A few of them also collaborate and work with local brands and start-up enterprises to produce new products.

Key Developments in FFS Rigid Films Market

In November 2024, Coveris announced a large investment to increase its technical film capacity. This program aims to increase the manufacturing of sustainable, recyclable films, such as advanced barrier and stretch films, in response to rising market demand for eco-friendly packaging solutions.

In October 2024, Klöckner Pentaplast introduced kpNext® MDR1, a new medical device packaging film that broadens the kpNext® brand beyond pharmaceutical blister films and into the medical device market.

Berry Global's European flexible films business will offer a new version of its high-performance, patented NorDiVent® form-fill-seal (FFS) film for powdered products in July 2024, with up to 50% recycled plastic content.

Key Players in FFS Rigid Films Market

Berry Global Group, Inc.

Algoja d.o.o.

RKW GROUP

Coveris

Mondi plc

AMB Spa

Klöckner Pentaplast

Jindal Poly Films

Fucine Film S.p.A.

Segers & Balcaen

Mountain States Plastics

Wipak Group (Wihuri)

Polifilm

FFS Rigid Films Market Segmentation

By Technology:

In terms of material, the FFS rigid films market is divided into polypropylene (PE), polyethylene (PE), polyvinyl chloride (PVC), polyester (PET), polyamide (PA), EVOH, PVDC and recyclable films.

By Thickness:

FFS rigid films are available in multiple thickness which include ≤50 microns. 50 to 150 microns, 150 to 300 microns and ≥300 microns.

By Packaging Format:

In terms of packaging format, the FFS rigid films market is segmented into blister packs, cup & containers, trays, clamshells, tubs and vacuum & skin packaging.

By End Use:

End user is the FFS rigid films market include food & beverages, pharmaceuticals, consumer electronics, industrial & automotive, personal care &cosmetics, retail & e-commerce and chemicals.

By Region:

Key countries of North America, Latin America, East Asia, South Asia and Pacific, Western Europe, Eastern Europe, Middle East and Africa are covered.

Authored by:

Ismail Sutaria (Lead Consultant, Packaging and Materials) has over 8 years of experience in market research and consulting in the packaging & materials industry. Ismail's strength lies in identifying key challenges faced by the client and offering logical and actionable insights to equip the clients with strategic decision-making power.

Ismail has been an instrumental part of several transformational consulting assignments. His key skills include competitive benchmarking, opportunity assessment, macroeconomic analysis, and business transformation advisory. Ismail is an MBA holder in Marketing and has a Bachelor's Degree in Mathematics.

Ismail is a regular at industry conferences and expos and has been widely covered in electronic and print media. He is a Speaker at our upcoming Talk show - Rise of the Intelligent Packaging. Ismail has been quoted in leading publications, including the European Pharmaceutical Review and the European Adhesive Tape Association.

Have a Look at Related Research Reports on the Packaging Domain:

The rising demand for printed plastic films is driven by their versatility in packaging, enhanced branding potential, and the growing need for durable, customizable, and visually appealing product presentations.

The global rigid food packaging market is set to gain a valuation of USD 197.5 billion in 2023. It is likely to exceed USD 317.7 billion by 2033, and exhibit a CAGR of 4.9% between 2023 and 2033.

The growth of packaging films is driven by increased demand for lightweight, sustainable solutions, technological advancements in material innovation, and rising consumer preferences for convenience and product protection in various industries.

In a recently updated edition, trends suggest a valuation of USD 80.6 billion for rigid box market in 2024. Sales of rigid boxes hold the potential to touch the valuation and even go beyond USD 96.3 billion by 2034. This indicates a CAGR of 1.8% during the forecast period.

The growing demand for flexible thin films is driven by their diverse applications in electronics, energy storage, wearable devices, and advanced packaging, offering enhanced performance, flexibility, and efficiency in modern technologies.

The global rigid IBC market is estimated to be valued at USD 19,531 million in 2024. Global demand for rigid IBCs is predicted to rise at a steady CAGR of 5.7% throughout the forecast period.

The usage of PE film has expanded across industries, providing versatile packaging solutions, excellent moisture resistance, and enhanced durability, making it ideal for food, medical, and industrial applications.

The rigid packaging container market is expanding at a 3% CAGR over the next ten years and lead the market to USD 275.2 billion by 2034.

The rigid industrial packaging market is expected to increase from USD 32,547.1 million in 2023 to USD 50,862.1 million by 2033. The market is likely to capture a 4.6% CAGR from 2023 to 2033.

The luxury rigid box market is projected to reach USD 6,200.7 million by 2034. Sales revenue is expected to increase at a CAGR of 3.8% over the forecast period.

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer, Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn | Twitter | Blogs | YouTube

SOURCE: Future Market Insights Inc.

View the original press release on accesswire.com